CONDUCTOR CEMENTING SUPPORT SYSTEM CAN SAVE SIGNIFICANT RIG TIME ON EACH CONDUCTOR BEING INSTALLED.

It has become increasingly common for operators to install a jacket, drill through the jacket structure and batch-set the platform’s conductors ready to install the topsides. This is followed by a rig being brought over the jacket and used to run the conductors. Traditionally the rig would have to hold each conductor in place while the cement cured, however, we have devised a vital time-saving solution.

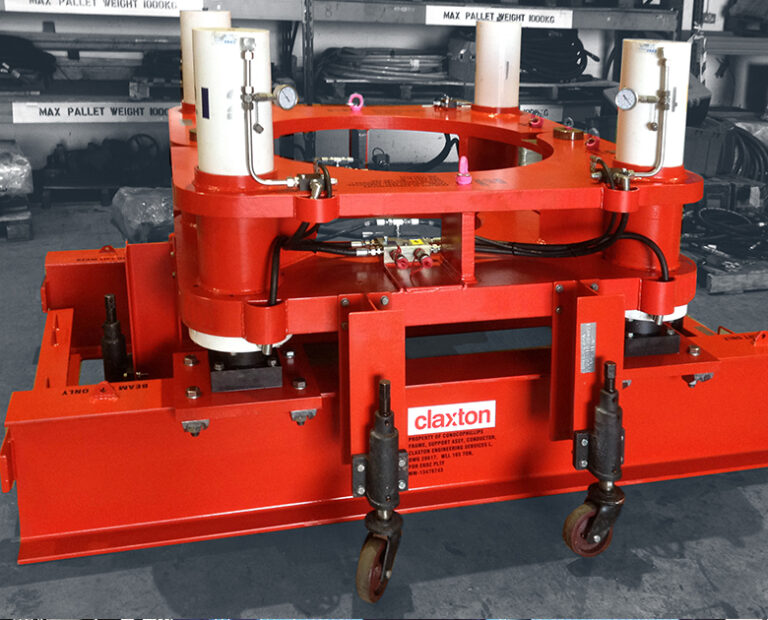

Tailored to operational requirements, the conductor cementing support system reduces rig time by between 12 and 18 hours per conductor during the cementing process. The low-profile design engages under the starter-head at the required height and is then hydraulically actuated to hold the conductor in position for the cement curing time. This removes the requirement for the rig to maintain the starter-head position and is free to skid over to the next slot to run the next conductor.

It is possible to increase efficiencies even further with this system by having two conductor cementing support systems running simultaneously on a project. Whether one or two systems are used, the process greatly reduces the time required to batch-set conductors and delivers significant rig time savings.

The financial benefit of the conductor cementing system is a clear choice when batch setting conductors. The system has proven itself in the field on projects for major operators in the North Sea.

Delivered by Claxton

Claxton combines a fast-track design and project engineering service with a large rapid call-off inventory to deliver integrated end-to-end life of field solutions for customers' renewable and oil and gas energy projects all around the world.

Integrate this product

Acteon can also offer an integrated project management service. This involves managing the activities of one or more of our companies on a customer’s behalf and providing a single point of contact for all aspects of project management.

DRILLING AND DECOMMISSIONING SERVICES - REQUEST MORE INFORMATION

Acteon’s expertise in drilling and decommissioning spans decades and covers the full lifecycle of a project from the acquisition of subsea information and data, to bespoke drilling packages to onshore disposal and recycling.

Similar products and services

-

Due to the varying designs of wellheads and Xmas trees, the use of polished rod...

-

Product and service line brand, Claxton, has successfully developed and deployed SWAT...

-

Offered with flexibility in mind, our drilling and pinning system can be provided as part...

-

MGR systems are commonly required for cleaning monopiles for offshore wind farms, prior...