Our range of friction welding services can provide an alternative solution for structural upgrade or remediation projects.

From subsea pipeline repair or cathodic protection retrofit, attachments of cofferdams to allow for repair to topside structural upgrade requiring a bolted solution or attachment of monitoring sensors as well as other offshore/onshore tasks, these systems have been proven to withstand the harshest of marine environments.

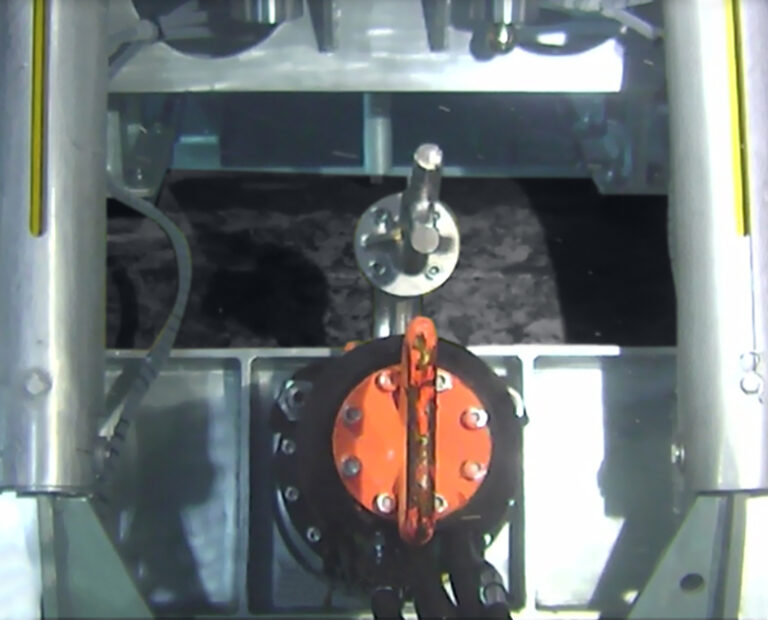

The HMS 3000 friction welding system

The HMS 3000 friction welding system is hydraulically powered and controlled via laptop and primarily used for subsea applications. The system can be fully integrated with an ROV or used by divers. The system can also be fitted with subsea stud changing capabilities. Common applications are the attachment of anodes on subsea structures, assets, live pipelines and FPSOs.

Delivered by Claxton

Claxton combines a fast-track design and project engineering service with a large rapid call-off inventory to deliver integrated end-to-end life of field solutions for customers' renewable and oil and gas energy projects all around the world.

Integrate this product

Acteon can also offer an integrated project management service. This involves managing the activities of one or more of our companies on a customer’s behalf and providing a single point of contact for all aspects of project management.

DRILLING AND DECOMMISSIONING SERVICES - REQUEST MORE INFORMATION

Acteon’s expertise in drilling and decommissioning spans decades and covers the full lifecycle of a project from the acquisition of subsea information and data, to bespoke drilling packages to onshore disposal and recycling.

Similar products and services

-

Acteon's internal wellbore sealing solution consists of an inflatable seal that sits on...

-

Onshore rigless conductor and pile installation service allows operators to drive and...

-

As part of the comprehensive conductor installation service, the conductor is cold cut...

-

Acteon have developed new designs and methodologies for the centralization of conductors...