Acteon offer a range of pipeline coating removal (PCR) systems powered by high pressure (HP) and ultra-high pressure (UHP) water, designed to remove concrete and other protective coatings from pipelines.

The system is capable of both linear and circumferential passes with only diver or ROV intervention necessary to cut the re-enforced bars exposed by the coating removal process.

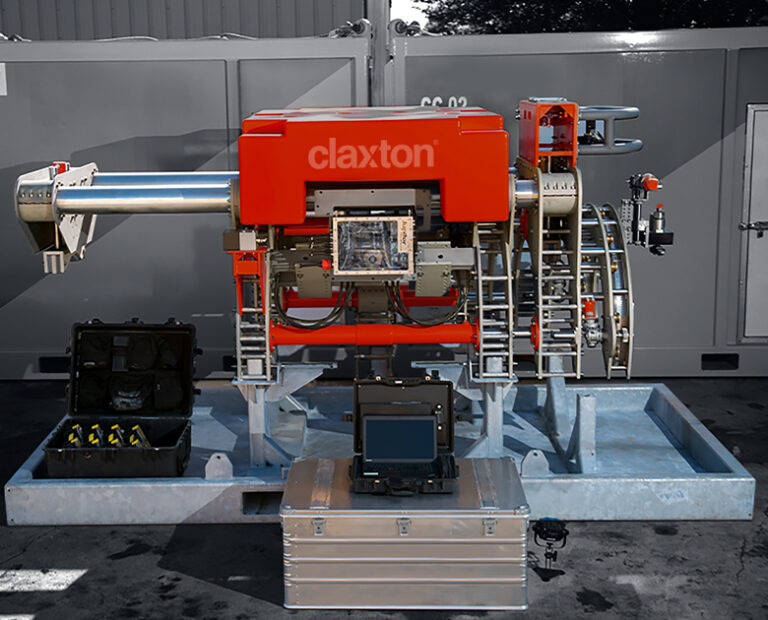

PCR technology is capable of removing coatings on pipelines ranging from 100 – 1200mm (4-48in) outside diameter, with systems designed to remove a 360˚ section of coating up to 1m in length. This is achieved by manipulating the jetting carriage using linear and circumferential movements, hydraulically controlled with fly-by-wire technology.

The PCR systems are fitted with rotating multi-jet heads to remove various coating types at the optimum rate. The electro-hydraulic supply and control can be operated from the surface or via the ROV subsea. All monitoring and adjustments are controlled via our in-house designed software.

Delivered by Claxton

Claxton combines a fast-track design and project engineering service with a large rapid call-off inventory to deliver integrated end-to-end life of field solutions for customers' renewable and oil and gas energy projects all around the world.

Integrate this product

Acteon can also offer an integrated project management service. This involves managing the activities of one or more of our companies on a customer’s behalf and providing a single point of contact for all aspects of project management.

DRILLING AND DECOMMISSIONING SERVICES - REQUEST MORE INFORMATION

Acteon’s expertise in drilling and decommissioning spans decades and covers the full lifecycle of a project from the acquisition of subsea information and data, to bespoke drilling packages to onshore disposal and recycling.

Similar products and services

-

Adjustable conductor guide centralizers are typically fitted at the splash zone level...

-

Acteon have developed new designs and methodologies for the centralization of conductors...

-

Grit blast cleaning systems provide fast and efficient cleaning to aid preparation for a...

-

We understand that every project has bespoke requirements and whatever the phase – from...