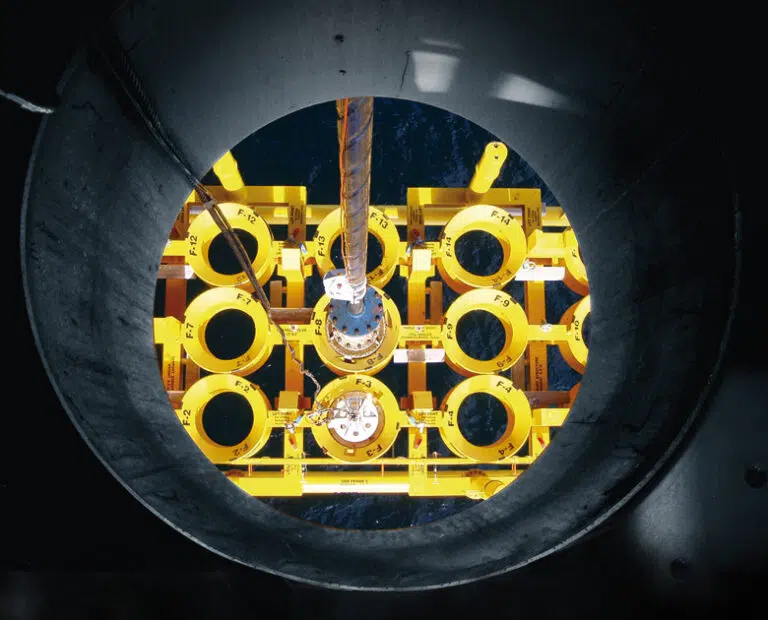

INCREASE THE EFFICIENCY OF OFFSHORE DRILLING PROGRAMMES WITH OUR RANGE OF DRILLING TEMPLATES. DESIGNED FOR ROBUST, SAFE AND RAPID INSTALLATION FROM A RIG OR VESSEL, THE TEMPLATES ENABLE SAFE PRE-DRILLING AND EARLY FIRST OIL.

Pre-drilling can be the most cost-effective option for developing a new field. Acteon is able to bring significant experience to the design of subsea drilling templates that will help to ensure operational success.

Every drilling template is designed for robust, safe and efficient installation, which can be either from a rig or pre-installed from a suitable vessel ahead of the rig’s arrival.

This flexible approach means that we have an enviable track record of designing, supplying and installing subsea drilling templates. Thanks to a large portfolio of pre-existing designs, drilling templates can be produced to tight timescales.

Delivered by Claxton

Claxton combines a fast-track design and project engineering service with a large rapid call-off inventory to deliver integrated end-to-end life of field solutions for customers' renewable and oil and gas energy projects all around the world.

Integrate this product

Acteon can also offer an integrated project management service. This involves managing the activities of one or more of our companies on a customer’s behalf and providing a single point of contact for all aspects of project management.

DRILLING AND DECOMMISSIONING SERVICES - REQUEST MORE INFORMATION

Acteon’s expertise in drilling and decommissioning spans decades and covers the full lifecycle of a project from the acquisition of subsea information and data, to bespoke drilling packages to onshore disposal and recycling.

SIMILAR PRODUCTS AND SERVICES

-

In recent news, The Scottish Government’s Just Transition Commission (JTC) announced it...

-

We recently conducted a survey where we asked our 12,000+ LinkedIn followers a series of...

-

Offshore infrastructure owners in the Middle East have long been looking for ways to...

-

If we can work together to apply fresh thinking, we can deliver outcome-driven solutions...