WE HAVE SUPPLIED MANY MAJOR RIG OPERATORS WITH RISER OR CONDUCTOR TENSIONING SYSTEMS THAT MITIGATE STRESS AND ENHANCE FATIGUE PERFORMANCE.

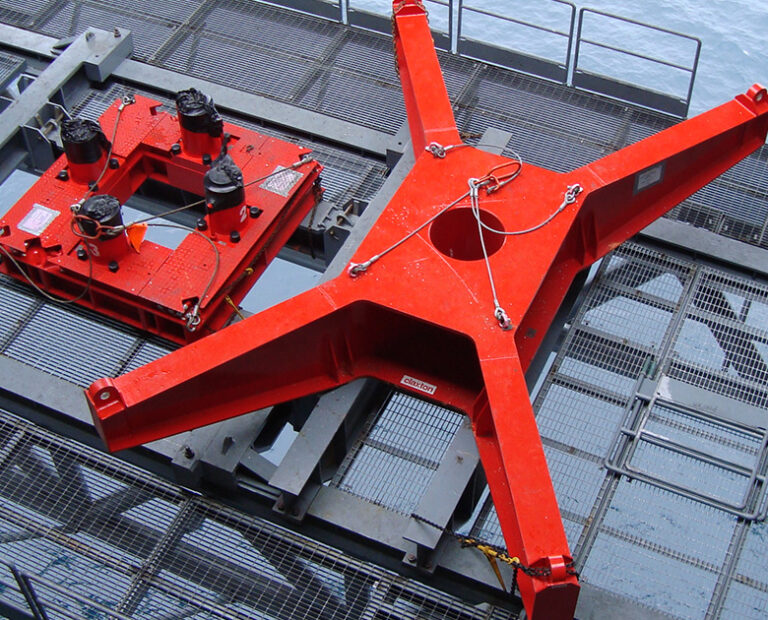

These systems apply a pre-calculated load (tension) to provide rigidity to the riser or conductor during drilling operations and reduce the applied axial loading from the blowout preventer stack and well control equipment.

As a system, riser tensioners need to be robust enough to withstand harsh environmental forces and be reliable throughout your drilling operation. Our riser tension systems are well-proven in the field and are supported by experience gained via our unrivalled subsea riser supply capability to most of the major drilling rig operators.

We can supply bespoke tension systems at short notice and has also supplied systems up to a record-breaking 1,000 tonnes.

With both sale or rental contracts available, we can supply complete systems including riser tension rings, c-plates and HPUs, or modular packages that will interface with your existing equipment or rig.

Delivered by Claxton

Claxton combines a fast-track design and project engineering service with a large rapid call-off inventory to deliver integrated end-to-end life of field solutions for customers' renewable and oil and gas energy projects all around the world.

Integrate this product

Acteon can also offer an integrated project management service. This involves managing the activities of one or more of our companies on a customer’s behalf and providing a single point of contact for all aspects of project management.

DRILLING AND DECOMMISSIONING SERVICES - REQUEST MORE INFORMATION

Acteon’s expertise in drilling and decommissioning spans decades and covers the full lifecycle of a project from the acquisition of subsea information and data, to bespoke drilling packages to onshore disposal and recycling.

Similar products and services

-

Supply of all types of pipe for a driven/piled foundation or conductor for onshore and...

-

The development of the tooling is supported by deep experience and knowledge of subsea...

-

Working closely with a network of approved European forges, mills, machine shops and...

-

From adding or recovering platform slots, replacing aged centralizers or adding a...